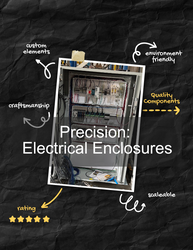

When your hydraulic system requires seamless control, precision matters—and so does the enclosure that powers it. At Flow Dynamics and Automation, we design and build custom electrical enclosures that do more than house components—they deliver reliable control, safety, and long-term performance in demanding environments.

We’re pulling back the curtain to show you how we engineer every detail with your operation in mind.

Built for Your Application

No two hydraulic systems are the same, and neither are our enclosures. We tailor every build to match your unique operational requirements—whether that’s managing multi-zone pressure, synchronizing actuators, or integrating with plant-wide automation.

We collaborate with your engineering or maintenance teams to ensure each component serves a purpose and supports your process.

Designed for the Environment

Industrial conditions vary widely. That’s why our enclosures are built to NEMA standards and designed to withstand:

- Dust and particulate exposure

- High-moisture or washdown areas

- Extreme temperatures

- Outdoor or corrosive environments

Durability is non-negotiable—our enclosures are built to last.

Top-Quality Components

We use only proven, brand-name components from trusted suppliers like:

- Allen-Bradley

- Siemens

- Eaton

- Phoenix Contact

- ABB

- Delta & Many Others

This ensures component compatibility, global support, and long-term availability for future maintenance.

Meticulous Layout and Wiring

A clean, organized interior isn’t just for show—it’s a sign of reliability and smart engineering. Each enclosure features:

- Thoughtful component placement for airflow and serviceability

- Clearly labeled, color-coded wiring

- Routed cable paths that minimize electromagnetic interference

We also include detailed schematics and labeling for fast field service.

Safety & Compliance

Every panel is built to comply with applicable safety codes and customer requirements, including:

- UL 508A for industrial control panels

- NEC and CE directives where required

- Customer-specific labeling or lockout standards

Safety is a priority at every step.

Tested & Integration-Ready

Before it leaves our facility, your enclosure is:

- Fully tested under power

- Verified for continuity and fault tolerance

- Simulated with your hydraulic system or PLC code

- Labeled and documented for easy install

This helps reduce startup time and unexpected issues during deployment.

Ready to Grow With You

We can design your enclosure with expansion in mind—space for future I/O, extra ports, or smart diagnostics modules. When your operation evolves, your control system will be ready.

The Flow Dynamics Difference

Our enclosures aren’t just equipment—they’re part of your system’s success. Backed by responsive support, expert engineers, and field-tested design, Flow Dynamics and Automation is the partner you can trust when precision matters.

Custom-built for performance—Flow Dynamics electrical enclosures are cleanly wired, clearly labeled, and integration-tested for control you can trust.